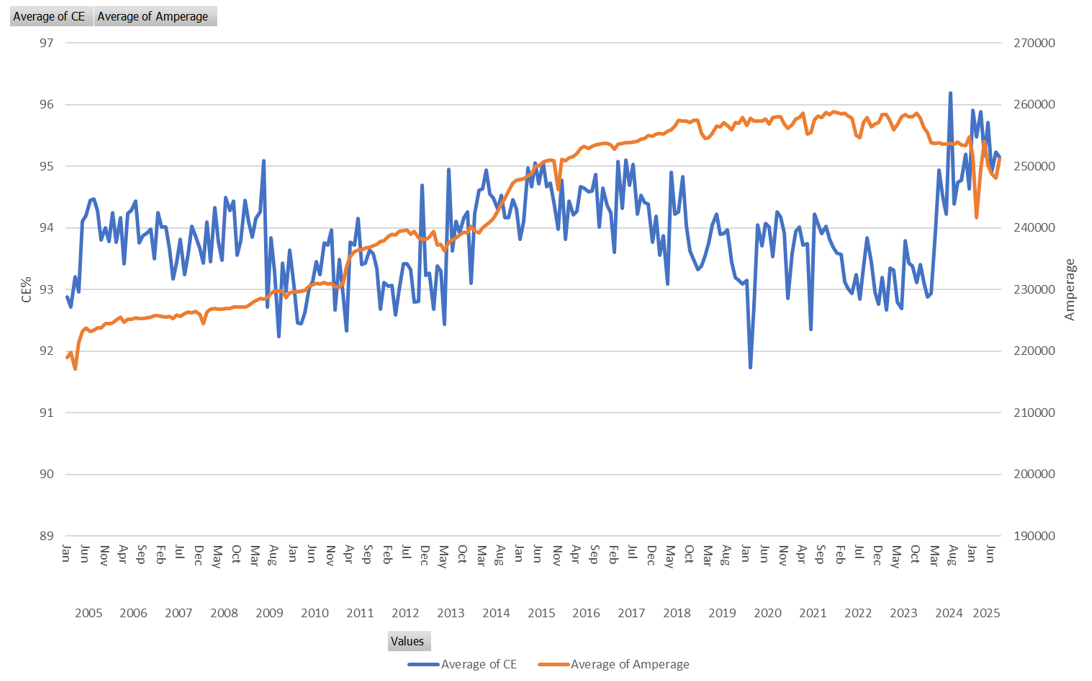

In a landmark achievement for the site, Tomago Aluminium has recorded the highest Current Efficiency (CE%) performance in its history, setting a new global benchmark for AP18 technology. This marks a TAC record since the introduction of AP22 (220,000 amps).

CE% climbed to unprecedented and sustained levels above 95%, as shown in the graph below. This milestone is the result of years of continuous improvement, disciplined process control, and a strong team culture focused on performance. It is also a real-life example of a ‘Blue Story’—those moments that highlight teamwork, achievement and care. Working together and SHIFTING to Blue, we’ve shown what’s possible when everyone pulls in the same direction.

Graph Above: Tomago Aluminium CE% and Amperage Performance (2005–2025)

Grant Farrow, Process Superintendent – Electrolysis, said: “Achieving this sustained level of performance is incredibly rare and sets a new Tomago standard.”

Three Key Drivers Behind the Record Performance:

- Improved Anode Quality

Enhanced manufacturing standards and tighter quality control have reduced variability and improved cell stability, directly boosting CE%. - Stronger Work Quality Standards

Consistent training, procedural discipline, and ownership of cell performance across shifts and crews have ensured sustained operational excellence. - LMO Process Team’s Continuous Improvement

The team’s relentless focus on bath chemistry, anode effect reduction, feeding control, and pot stability has been pivotal in reaching this record.

This achievement reflects Tomago’s values of Care, Teamwork, and Achieve and we would like to congratulate everyone involved.

Looking ahead, we’ll continue refining that “sweet spot” of operational excellence and resilience, driving Tomago to even greater performance records.